22 August 2022 - A research team at the University of Virginia has developed a unique bio-building technology that could change the current stage of people's, sustainable ideas about the future of environmentally friendly buildings.

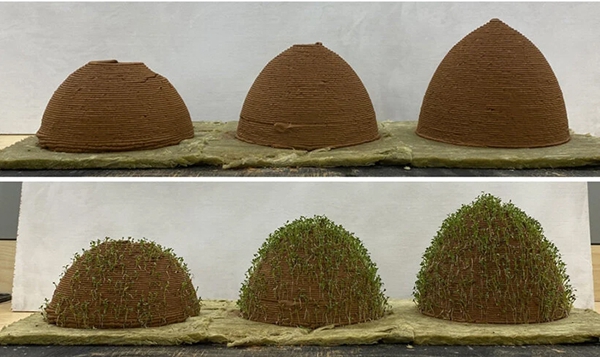

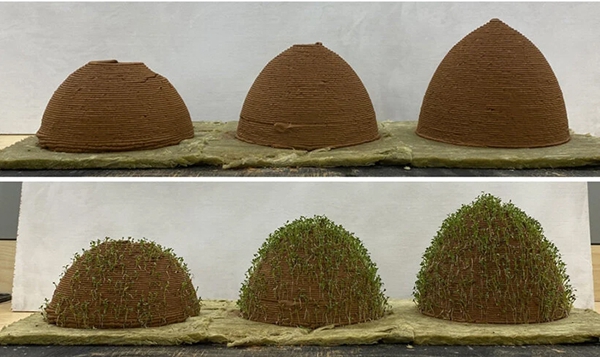

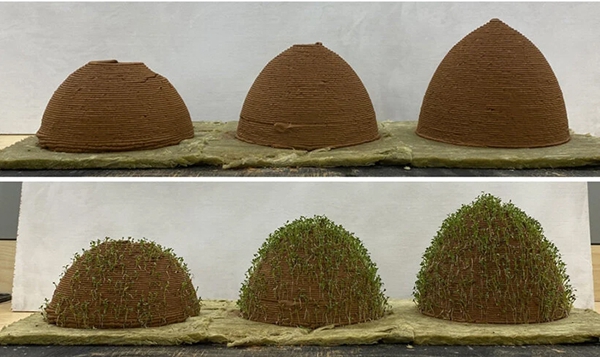

△ Using 3D printed soil to construct buildings and successfully grow plants

The team says that through a series of 3D printing techniques consisting of soil and seeds, for example, the development of a new 3D printed material for buildings, they make architectural structures into arbitrary geometric shapes while giving the buildings the ability to grow plants themselves. The perfect integration of implantation and architecture. As the experiment progresses, it will now be investigated how, on a larger scale, this technology could become the cornerstone of future housing. To conduct the experiment, Ji Ma, an assistant professor in the university's School of Engineering and Applied Sciences, joined forces with David Carr, a research professor in the Department of Environmental Sciences, and Ehsan Baharlou, an assistant professor in the School of Architecture, and his student Spencer Barnes.

The research team at the University of Virginia believes that they are contributing to new ideas for the future of the construction industry. With innovative 3D printing technology, the future could meet the global demand for cheaper housing, green buildings and meet the growing demand for circular economy systems.

△The project has been published in the journal Additive Manufacturing:

https://www.sciencedirect.com/science/article/abs/pii/S2214860422000756#!

Exploring sustainable additive manufacturing technologies

We turned to developing soil-based 3D printing materials to get additional benefits from circular additive manufacturing, explains Ehsan Baharlou: "We use local soil and plants mixed with water, and the only electricity we need is to use some during the printing process. When we don't need to print the building again, or it's not the right quality, we can reuse the materials by recycling and reusing them in a single job."

After several rounds of testing the soil mixture, the structures were able to grow a certain number of plants, but not all of them at the moment, Ji Ma notes, "Normally, 3D printed soil tends to lose moisture quickly and, at the same time, dries out the environment around the plants, so we have to incorporate plants that prefer a dry climate into the soil, and the reason we think that is because the soil is compacted. When the soil is squeezed through the nozzle, the air bubbles are pushed out and when the soil loses the air bubbles, it holds on to the moisture."

△Ehsan Baharlou is testing soil-based 3D printing materials

Driving a reduction in carbon emissions

The most immediate application of this technology is probably not in architecture, but in landscape architecture," says Ma. The way the soil is printed and the amount of water supplied, it can effectively simulate different climatic conditions around the world. You may have the ability to grow different species in the same place that are normally adapted to different environments. It is possible for landscape architects to create zoos of different plant species if you wish."

Ultimately, the goal here is to promote the practice of reducing the carbon footprint of buildings by using locally sourced biological materials. This means that 3D printing can replace non-recyclable, non-reusable and traditional resources. Biobuilding thus opens the door to low-cost, low-energy and climate-friendly alternatives in architecture and engineering.