Japanese precision equipment manufacturer Sugino Machine Limited has introduced a hybrid manufacturing system that combines CNC machining with laser metal deposition (LMD) 3D printing

Oct. 17, 2022 - Japanese precision equipment manufacturer Sugino Machine Limited has introduced a hybrid manufacturing system that combines CNC machining with laser metal deposition (LMD) 3D printing. The "XtenDED" model is said to be capable of producing and finishing parts with higher throughput and precision by integrating the hybrid manufacturing technology AMBIT print head and CNC machining head. Thanks to its compatibility with nickel superalloys, cobalt-based superalloys and stainless steel, the machine can meet demanding aerospace applications where heat resistance is critical.

Sugino's existing equipment

Originally founded in Japan in 1936, Sugino's operations have focused on manufacturing systems for high-pressure cleaning, deburring, machining, drilling, tapping, polishing, and water jet cutting of parts. Over the past 86 years, the company has expanded significantly, opening a U.S. division in 1980, but it continues to focus on helping customers improve manufacturing reliability, flexibility and accuracy.

Most of Sugino's current product offerings are geared toward post-processing and include everything from high-pressure cleaning and deburring machines to dry blast milling systems and polishing tools. Sugino's portfolio has long included a range of CNC machining centers and modules. The company's Xion-II 5AX compact precision 5-axis center is designed for precision machining while maximizing footprint and operating costs at up to half that of competitors. Meanwhile, for the H-720, Sugino has introduced a horizontally designed system that is ideal for mounting on indexing machines.

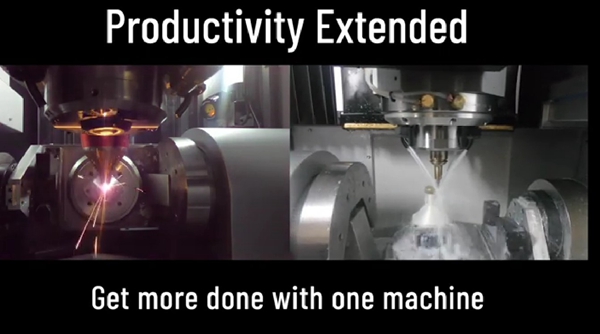

△ Hybrid deposition head for the SuginoXtenDED 3D printer. Photo from Sugino.

XtenDED Manufacturing Capabilities

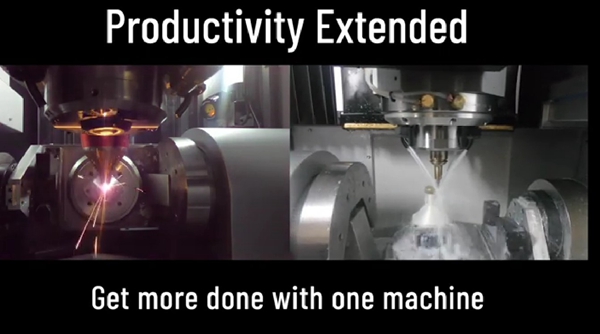

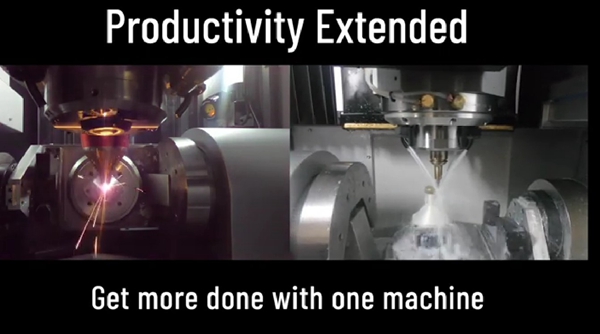

At the heart of the XtenDED is a dual-head unit that combines an AMBIT laser processing head with a CNC machine's tool magazine.Hybrid Manufacturing Technologies' AMBIT head combination is designed to turn the machine into a hybrid production, finishing and inspection tool, making it ideal for Sugino's dual-function system.

On the XtenDED, the print head melts the powdered material as it reaches the surface of the part through the use of a laser, and as this material cools, more layers can be added on top. By placing the CNC machining head directly next to this Directed Energy Deposition (DED) technology, the unit's developers say it can post-process parts with greater precision while increasing productivity on the shop floor.

Because LMD uses less energy and is more controllable layer-to-layer, Sugino claims that XtenDED also has a "significantly smaller heat-affected zone (HAZ)" than plasma or wire-based 3D printers. The company adds that this makes the manufacturing system "more wasteful than machining alone and more efficient and accurate than 3D printing alone," while allowing it to offer users the best of both technologies.

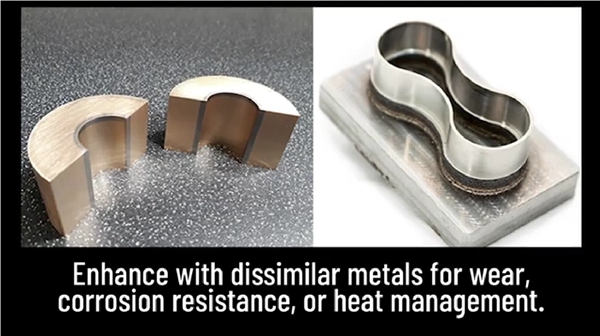

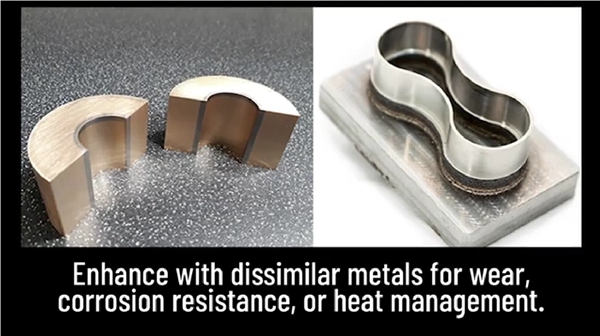

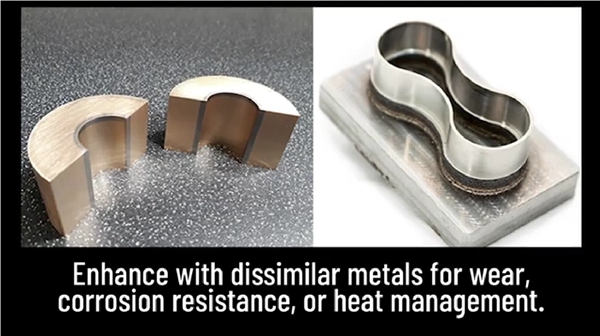

In practice, the 300 x 400 x 200 mm machine is said to accelerate the product design to manufacturing process while addressing prototyping applications and enabling metal part repair and surface resurfacing. sugino is also marketing XtenDED as a way to combine different alloys to give components corrosion or heat resistance, a process that can be completed in minutes.

Sugino's XtenDED hybrid 3D printer. Photo from Sugino

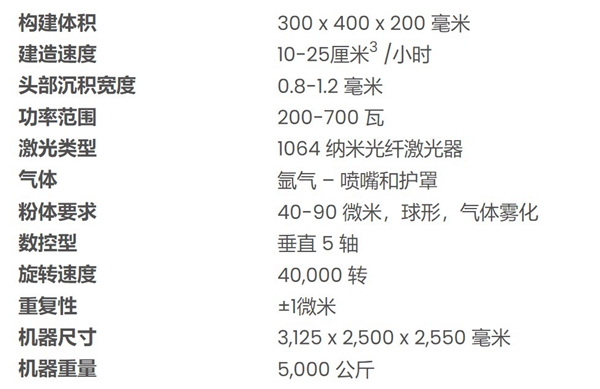

Technical specifications and pricing

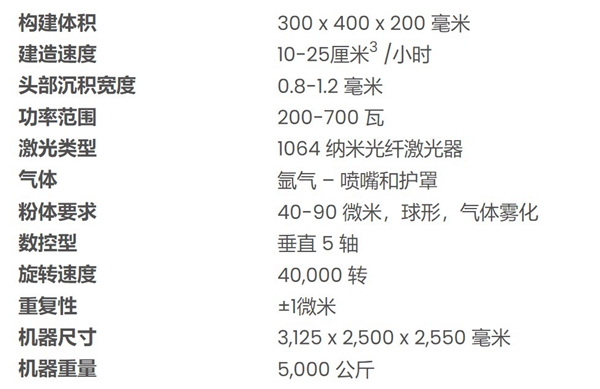

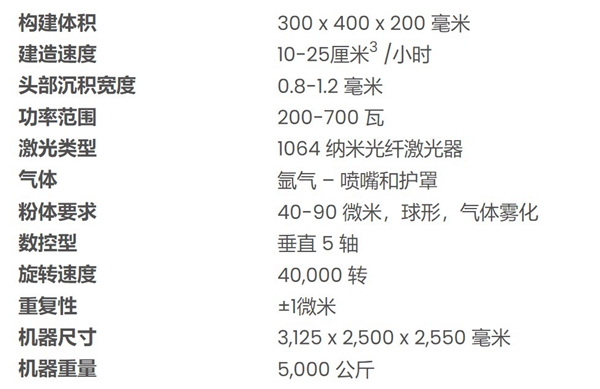

Here are the technical specifications for Sugino's XtenDED 3D printer.