11 June 2022 Axle Box Innovations, a developer of co-security technologies, is using additive manufacturing techniques to support the development of 3D printed drones for fire management and protection.

Introduction: Wildfires are a disaster that, once ignited, can spread at an average speed of 22 kilometres per hour and are increasing dramatically in number, frequency and severity worldwide, with major impacts on economies, ecosystems and communities. Walking firefighters take about four minutes to travel, so it is unlikely that firefighters can outpace the speed at which fires spread, especially when high winds are blowing. Often, when a fire breaks out, firefighters do not have enough time to barricade and block the road. In such emergencies, the development of drones that can be used to fight fires is starting to receive more and more attention.

11 June 2022 Axle Box Innovations, a developer of co-security technologies, is using additive manufacturing techniques to support the development of 3D printed drones for fire management and protection. In recent years, fire has become a growing threat in the United States and other countries around the world, destroying countless homes and entire communities and causing billions of dollars in damage.In 2021, 8,619 fires burned nearly 2.6 million acres of land, making it a record year for forest fires in the U.S. Axle Box turned to 3D printing technology research to help address the creation of fire safety drones the strength, speed and cost hurdles.

△3D printed drones for fire prevention

To be able to respond to the increasing number of fires, firefighters are increasingly relying on innovative technologies such as additive manufacturing. When faced with a new fire outbreak, firefighters must have an accurate picture of the situation. In order to gain quick access to the situation, firefighters need special drones that have the ability to get close to the flames and analyse the extent of the outbreak, in particular to calculate the number of fires present in certain areas. Unfortunately, ordinary commercial drones are not suitable for getting close to fires because their materials and technical equipment cannot withstand high temperatures.

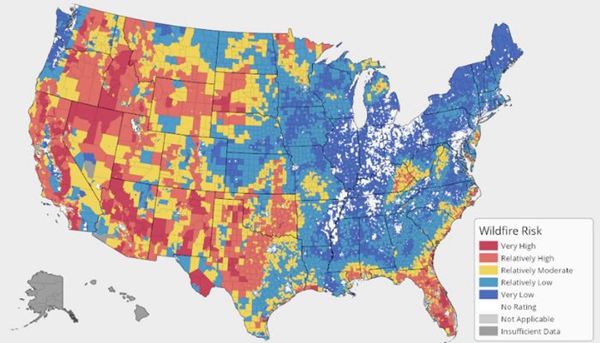

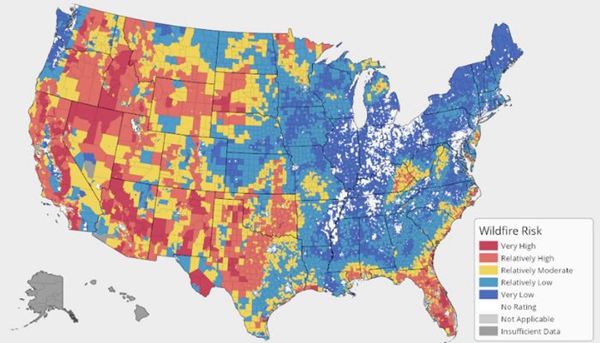

△ Map showing areas of highest fire risk. Fires have increased over the years due to global warming, especially in dry areas like the West (image credit: FEMA)

Creating safe drones that are fireproof

In their search for the right technology and materials to develop heat-resistant drones, engineers at Axle Box found a solution provided by Essentium, Inc. Dr. Blake Teipel, CEO of Essentium, commented: "As first responders prepare for fire season, firefighters need flexible, remote-controlled drones to enable the visualisation of almost visual surveillance of fires in all types of environments - from urban areas to rural deserts. We are delighted that Axle Box Innovations has chosen our 3D printing platform to enable the development of structurally robust drones that can withstand these extremely harsh conditions."

The material used to create the fireproof drone is a high temperature nylon with a core of 25% carbon fibre. It will be used in the mid-body of the drone as well as the side covers, which will ensure that the drone retains its shape and function when exposed to high heat. In addition to its inherent heat resistance, the material also allows for the creation of lightweight and robust drone bodies, a key component when it comes to flight and safety applications. For the actual manufacturing process, Axle Box chose Essentium's High Speed Extrusion (HSE) 3D printer, which uses an independent dual extrusion (IDEX) system and filament.

△ Image source. University Park National Archives - still image

MadisonJones, Axle-Box's Director of Additive Manufacturing, concludes: "The speed, scale and economy of the HSE 3D printer combined with Essentium's advanced 3D printing filament array is a game changer in the design and development of UAV platforms. HSE has been a game changer on our production floor, where we typically go from design to production in four weeks . If we need a new part, we can have it printed and ready to go in a matter of hours. Our first responder customers will benefit greatly from the agility of this innovation." Exactly when the drones will play a role in the fight against fires is yet to be revealed, but with the right technology and materials already at hand, production is likely to be completed soon.