Read more: Heart disease has topped the list of deadly diseases worldwide for the past 20 years, with more deaths from heart disease than ever before, according to the Global Health Assessment 2019 report published by the World Health Organization in December 2020. Since 2000, the number of deaths from heart disease has increased by more than two million, rising to almost nine million in 2019.

Many of these patients with serious conditions require a heart transplant, yet this waiting period is always too long and it is not uncommon to wait more than six months or even before the time of life runs out. The need for a more effective alternative to heart tissue is a pressing need for the medical community, and 3D bioprinted heart technology is one of the proven solutions.

On 12 June 2022, Jennifer Lewis's team from the Wyss Institute for Bionic Engineering at Harvard University and the Harvard School of Engineering and Applied Sciences (SEAS) collaborated to develop a new heart engineering technique. The technique simulates the complex arrangement of the heart's contractile elements while producing tissue thick enough to be used for regenerative heart therapy.

An improvement on the existing SWIFT 3D bioprinting technology

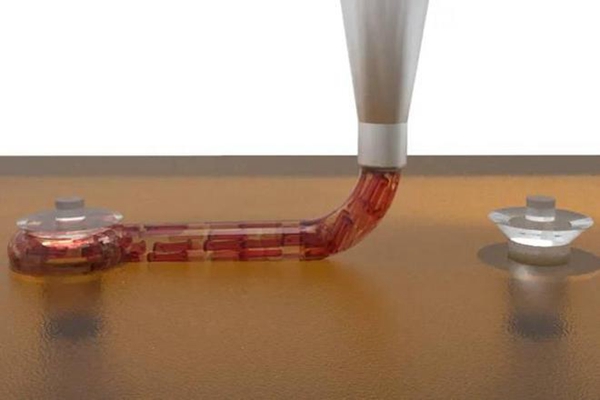

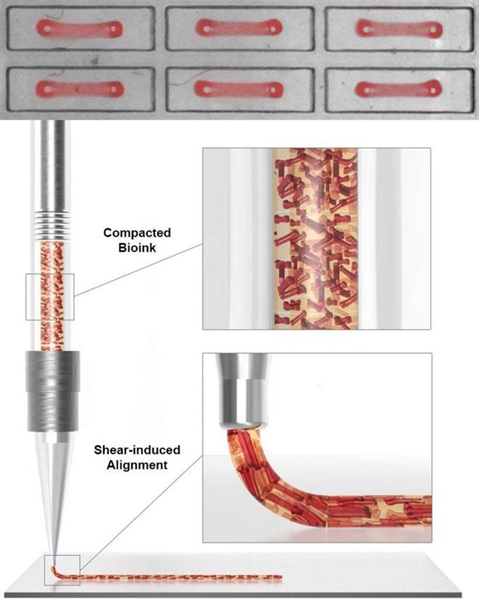

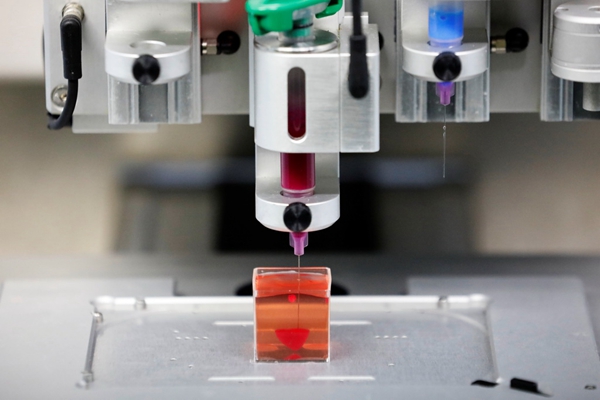

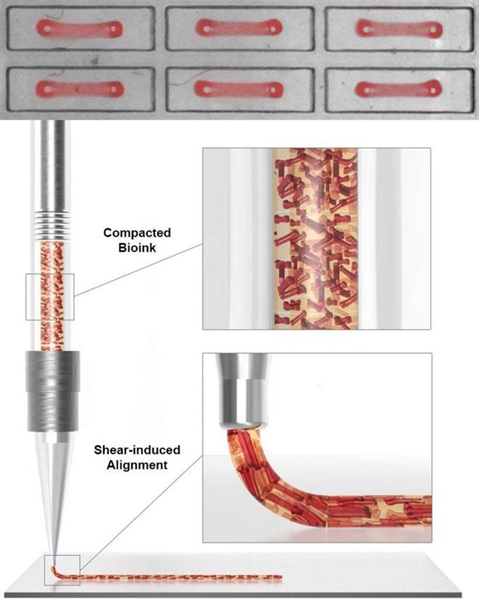

The set builds on the existing SWIFT bioprinting platform, which has 1050 holes, each containing two micro-pillars. The researchers first formed pre-assembled cardiac organ building blocks (OBBs) by artificially inducing pluripotent stem cell-derived cardiomyocytes (hiPSCs-CMs), which were then removed from the micro-pillars and used as feedstock for the manufacture of bio-ink, and further aligned during the printing process using the motion of the 3D printer head.

Δ3D bioprinting process

Following experiments, the team was able to print thin slices of heart tissue with a complex and variable arrangement similar to the layers of actual human heart muscle, which will hopefully pave the way for 3D printed heart tissue replacements.

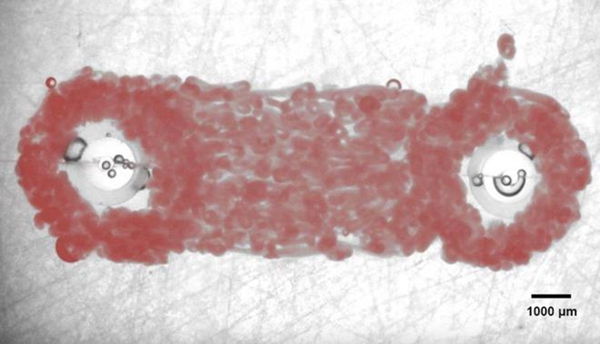

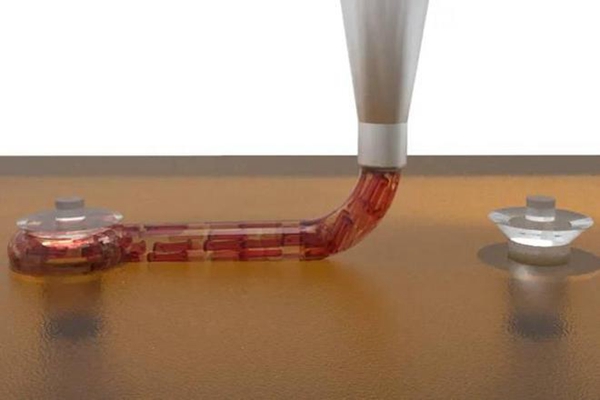

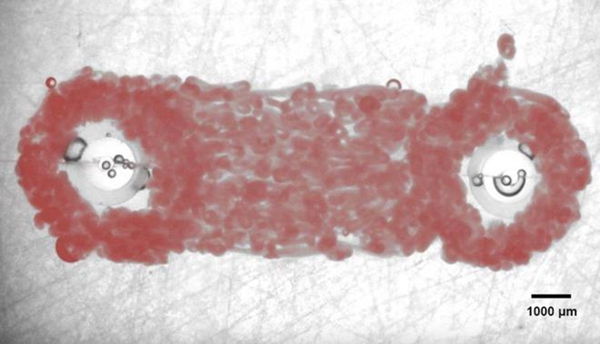

To test the contractile characteristics of the printed heart structure, the researchers also printed 'large filaments' connecting two large columns, and measured that the contractile force and contraction speed produced by the filaments increased over seven days, suggesting that the heart filaments were able to continue to mature into true muscle-like filaments.

3D bioprinted heart cells

This also means that the new technology is able to effectively mimic the arrangement of the heart's contractile system throughout the hierarchy from individual cells to thicker heart tissue made up of multiple layers, which is essential for generating functional heart tissue for alternative treatments.

With this technology in the future, it could be used to generate more physiological disease models and create highly structured heart muscle patches that, like Lego blocks, could be matched and used to replace patient-specific scars after a heart attack.

Similarly, they can be customised to repair patient-specific 'holes' in the hearts of newborns with congenital heart defects, and these patches can develop with the child without having to be replaced as the child grows.

Other advances in 3D bioprinted heart tissue

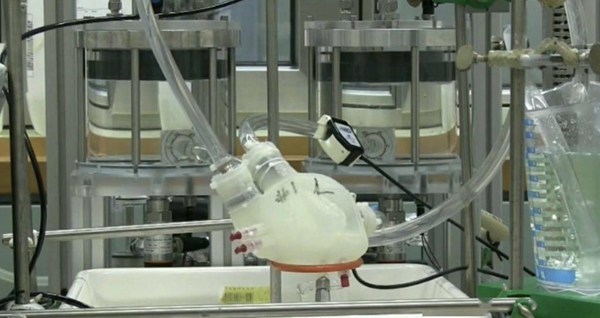

Back in 2017, a team of researchers at ETH Zurich used 3D printing technology to create an artificial silicone heart that could beat like a human organ, but tests at the time showed it lasted only 30 to 45 minutes.

△Image from: ETH Zürich

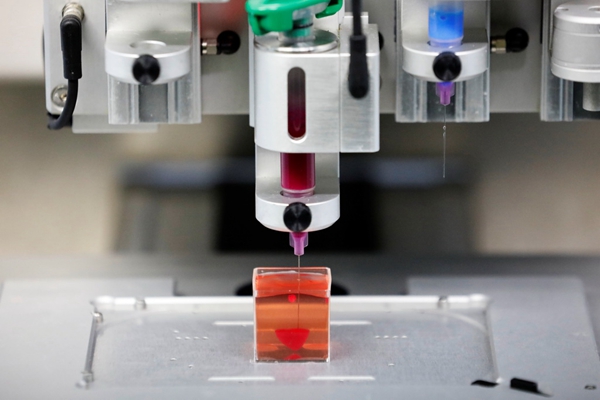

In 2019, researchers at Tel Aviv University in Israel created the world's first 3D printed heart with cells and blood vessels. The researchers harvested fatty tissue from a patient and separated the cells from the non-cellular material. The isolated cells were then mixed with a specially designed printing material to print heart tissue suitable for the patient. Although this is a fully constructed heart including blood vessels and ventricles, it is the size of a rabbit's heart.

△Image from: Wyss Institute

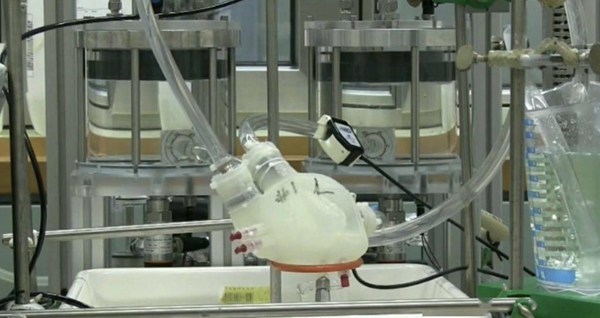

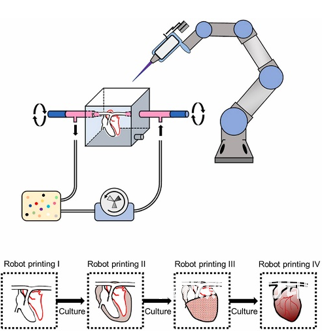

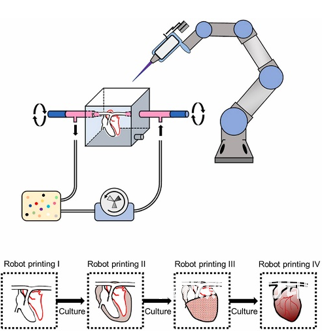

In June 2022, a team of researchers from the Chinese Academy of Sciences and Tsinghua University in China, creatively transformed a six-axis robot into a bio-3D printer - a six-axis robotic bio-3D printer that enables 360° all-round arbitrary angle cell printing; and developed an oil bath cell printing system to better maintain the natural functions of the cells after printing. Combined with a self-designed bioreactor and a repeatable print culture strategy, the bioprinting system is capable of generating vascularised, contractible, long-term viable heart tissue, providing a promising solution for the in vitro fabrication of complex organs.

△ Schematic of the six-axis robotic biometric 3D printer

While there is still a long way to go before a fully functional complete heart can be 3D printed, the advent of this technology is a great breakthrough and may not be far from the day when an artificial heart can be replaced.