Microlight3D, a specialist manufacturer of high-resolution, micro 2D and 3D printing systems for industrial and scientific applications, June 2022, has launched eight new resins with different properties for mechanical metamaterials and life science applications, according to mohou.com.

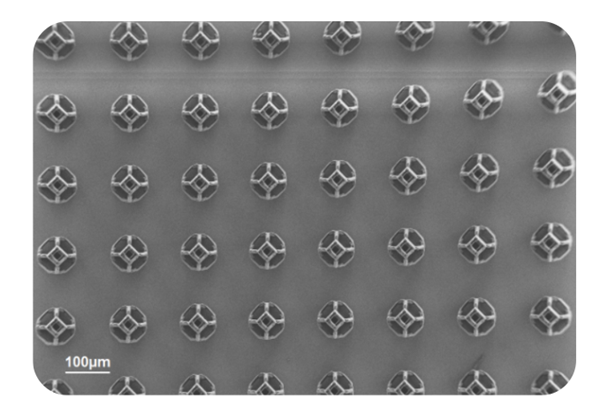

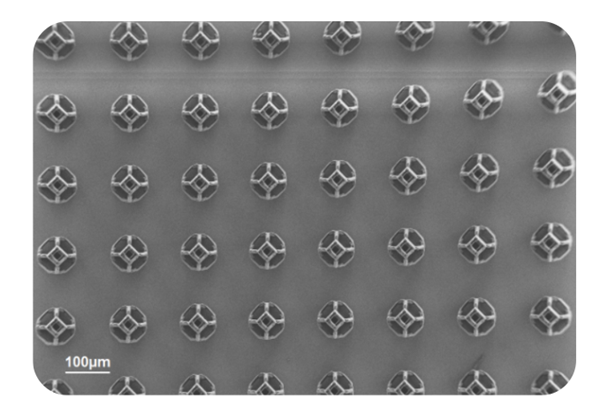

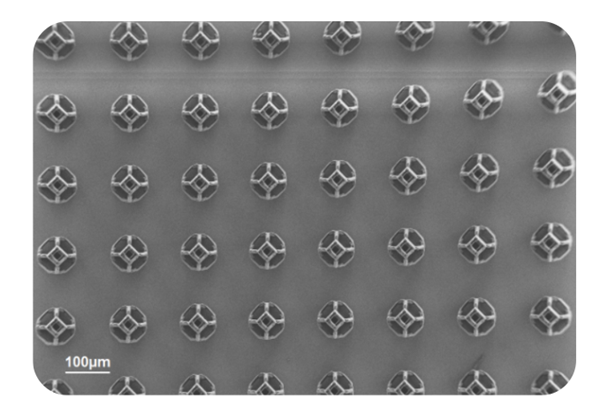

The range of resins launched is highly flexible, rigid and biocompatible, creating opportunities for developers to explore 3D microprinting using different materials. The range is also capable of reproducing tiny objects, up to 100 times smaller than a hair, in complex designs. In addition to the two resins already on the market, Microlight3D has developed eight more resins for its microFAB-3D - an ultra-high resolution, two-photon polymerisation printing system. Direct laser writing technology is used to create solid 3D printed structures from photoactivatable materials.

△MicroFAB-3D

We are pleased to offer a wider range of resins that will allow our users to take full advantage of our 3D micro-printing systems," said Philippe Paliard, head of Microlight3D's 3D printing lab. Many traditional 3D printing resins do not automatically use the two-photon polymerisation method, but our newly developed resins break with tradition."

Δ6 mm high microstructure pulling and expanding scaffold. Manufactured with μFAB-3D.Advanced

The resin used for microFAB-3D is easy to apply and remove , only a drop on the substrate (glass coverslip) is needed to run micron-sized print jobs and a 10-minute solvent bath go removes the unused resin. If another material is desired, the user can simply place a drop of a different resin onto another glass coverslip. Alternatively, the user can simply print using the previously rinsed coverslip, thanks to the alignment function in the Microlight3D machine software.

● Microlight3D offers two rigid resins, Rigid-A and Rigid-E, as well as a flexible resin called Flex-A, for use in the field of mechanical metamaterials, including 4D printing and micromechanical applications such as miniature clamps, screws and microstructured materials - to obtain a unique combination of material properties combinations.

Parts made from Flex-A flexible resin

● Mechanical metamaterials researchers also have the option of OrmoRed, a resin that is activated using an infrared laser. MicroFAB-3D therefore has the unique ability to combine two different wavelengths of laser light, enabling researchers to use different materials in the same system - enhancing OrmoRed resin with metal or magnetic nanoparticles to create, for example, micro-robots.

● Microlight3D has also developed OrmoBio and Green-A-Bio as biocompatible resins, and Green-Gel and UV-Gel as biocompatible and ductile hydrogels. green-Gel and UV-Gel allow for ultra-high resolution printing and have properties that can be tailored to the user's needs. The high stiffness of this regulated hydrogel plays an important role in cell culture, as cell interactions are influenced by the stiffness of the surrounding material.

Paliard adds "In addition to the ten proprietary resins we now offer, our system is also compatible with polymeric materials for micro-optics, UV resins for microfluidics, cell culture and micro-optics. The system can be used with several resins certified for the production of medical devices for highly complex implantable microneedle or